Across a wide range of industries, ULVAC is a source of numerous products and technologies that meet the needs of our customers and the market.

ULVAC's base technology with vacuum technology at its core and related peripheral technologies have been combined through many years of R&D and improvements in manufacturing technology, enabling us now to deliver a very wide range of industrial manufacturing equipment for semiconductors, electronic parts, flat panel display, solar cells, and others.

ULVAC, as a general manufacturer of vacuum equipment, also focuses energy on the development of components in order to offer a wide-range component line-up.

ULVAC delivers all types of products ranging from components such as vacuum valves, flanges and terminals, to vacuum pumps and measurement and analysis equipment.

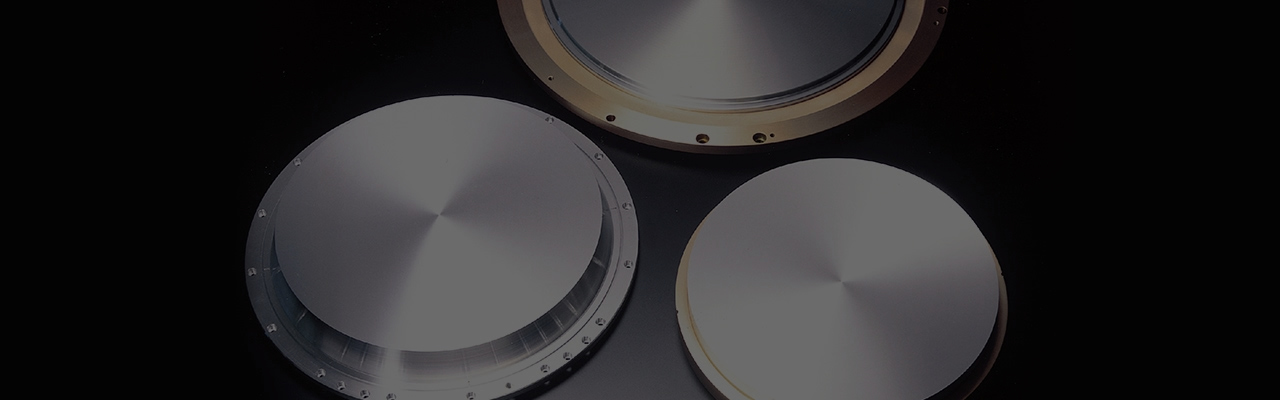

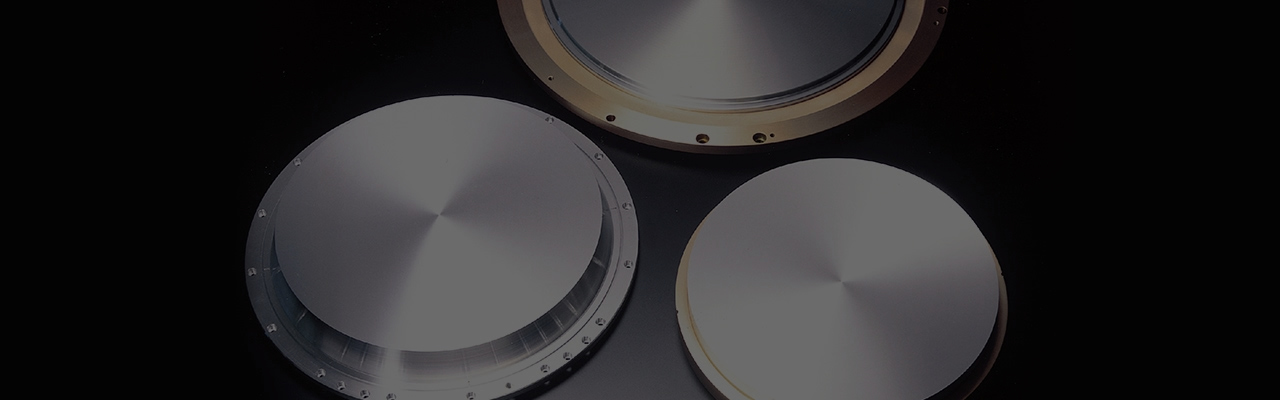

ULVAC’s global production system delivers high quality, stable and low-cost supply of sputtering targets and various vapor deposition materials by making maximum use of its best features as an equipment manufacturer.

ULVAC facilities also include the Institute for Super Materials which is a professional R&D facility for new materials. ULVAC also works closely with nearby production plants to support a broad range of needs ranging from trial production of samples for next-generation materials, to material supply and technical consultations on mass production line operation.

To develop and produce high-quality sputtering targets, ULVAC carefully evaluates which manufacturing method to use for each material to meet the product quality goals "Low particle", "Good film uniformity" and "High usage efficiency".