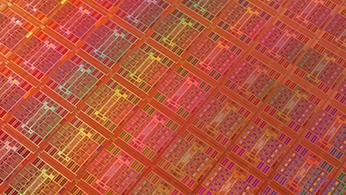

The requirements of semiconductor devices and related components are evolving to support the emergence of IoT's big data demand and servers for edge computing. Growth opportunities are increasing not only for traditional DRAM and NAND but also for storage class memory consisting of non-volatile memory.

Miniaturization is fueling innovation in processor technology. Amid these technical innovations in semiconductors, in addition to NAND and DRAM memory, ULVAC positions PCRAM and the logic/foundry business as the axles of growth.

We will focus on growth engine keywords: “Miniaturization process requirements”, “Non-volatile memory deposition”, “Wafer level package deposition”, and “Logic/Foundry miniaturization mass production support”. Based on a business growth strategy unique to ULVAC, we will pursue business development different from other major competing equipment manufacturers.

As for mid-term strategic products, we are promoting the development of leading-edge technologies that leverage our strengths in the native oxide removing system and sputtering system.

Technology will continue to evolve at a faster pace, including IoT, which enables everything to connect to the Internet; big data, which analyzes and generates new value in huge amounts of data; AI, autonomous driving, and EV, which have been made possible thanks to advanced high-speed information processing technology.

A new socio-industrial structure, with new auto industries, is just around the corner. We globally engage with customers in fields, such as non-volatile memory, 3D-IC, telecom devices, sensors, and optoelectronics devices, to develop innovative vacuum technology and help customers realize development and/or scaling production.

In Europe and North America, where many new devices are being developed, we are cultivating collaborative relationships with customers through collaboration among Group companies. To play the role of a trailblazer, we aim to vigorously cultivate new customers.

In Asia where many of our customers have production bases, we will vigorously implement activities to expand sales while strengthening innovative proposal capabilities in addition to building on our delivery track record so far. Through these initiatives, we aim to expand business globally.

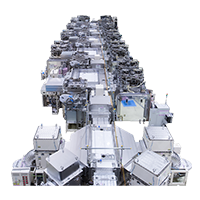

ULVAC is recognized as the global leader holding top class in sputtering systems for liquid crystal display applications. We provide state-of-the-art vacuum technology for Organic LED mass production equipment and develop next-generation display technology. We provide solutions from R&D to scaling and support for our customers in the FPD such as TVs, smartphones, PCs, and tablets.

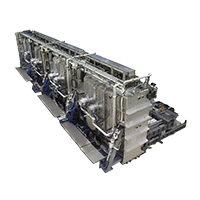

ULVAC has been at the forefront of industrial equipment manufacturing since its founding, contributing to the growth of heavy industries for steel and metal and to the automobile and home appliance industries.

Today, we are making full use of the fundamental technologies we have cultivated so far to manufacture vacuum melting and vacuum sintering furnaces for rare earth magnets used in EV drive motors, vacuum sintering furnaces for manufacturing tantalum capacitors, and vacuum brazing furnaces for heat exchange parts. We also develop furnaces for manufacturing silicon wafers.

In the field of life sciences, we have developed pharmaceutical applications such as lyophilizers (freeze drying), centrifugal thin film evaporators and high-purity refining of Vitamin E, Eicosapentaenoic acid (EPA) and Docosahexaenoic acid (DHA) using vacuum distillation.

As a comprehensive vacuum product manufacturer, ULVAC is also dedicated to the development of components.

ULVAC pursues cutting-edge vacuum technology while providing a wide range of product lines, extending from vacuum pumps, measurement and analysis equipment, vacuum gauges that measure vacuum (pressure), process gas monitors that identify gas type, helium leak detectors that identify leaks to maintain the vacuum, power generators for various types of deposition equipment and vacuum valves.

In the electronic materials field, we provide high-quality, high-efficiency advanced materials in vacuum technology to the world market.

We supply thin film materials (mainly sputtering targets) used in the deposition process of semiconductor / electronic devices and FPD contributing to the development and production of state-of-the-art devices.

We melt, process, and manufacture adjusted to customers' need for high melting point metal (e.g. tantalum, niobium) parts used in high functional material applications such as electronic devices, chemical industry, medical industry and electronic accelerators.